Newsletter 2018.3 Index

Theme : "The Ninth JSME-KSME Thermal and Fluids Engineering Conference (TFEC9)"

|

Numerical Simulation of Solidification and Deposition of Single Molten Droplet by Means of E-MPS Method

|

|

|

|

| S. KONDO Tokyo University of Science |

H. MAMORI Tokyo University of Science |

N. FUKUSHIMA Tokai University |

M. YAMAMOTO Tokyo University of Science |

Abstract

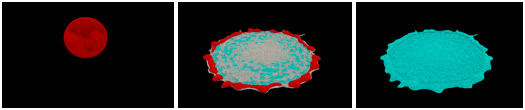

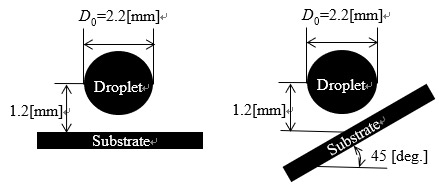

Sand and volcanic ash in the air are ingested into jet engines and these pass through a combustion chamber. Due to the high temperature in the chamber, sand and ash are melted and they become the molten droplets. Because the molten droplets are rapidly cooled around the turbine blades and the end walls, the droplets are solidified and adhered on these surfaces. The deposition phenomenon of the molten droplet deteriorates the turbine performance and causes serious problems. In order to clarify its mechanism, the behavior of a single molten droplet adhering on the cooled substrate is expected to bring important information. Therefore, the present study carries out three-dimensional numerical simulations of a single molten droplet adhering on cooled plane horizontal and inclined substrates by means of an explicit-moving particle simulation (called as E-MPS) method. Figure 1 shows a time series of snapshots of a colliding and adhering molten Sn droplet when the collision angle is 90 degrees. We observed that the molten droplet collides, spreads, and solidifies on the cooled substrate. The behavior shows the reasonable agreement with the existing experimental data not only in the horizontal substrate case, but also in the inclined case. We observed that the finer-like-structure around the adhered droplets in both the cases, which is the typical structure in the droplet deposition. The results are expected to contribute to predict the deposition phenomenon in the gas turbine.

Key words

Deposition phenomena, E-MPS method, Single molten droplet, Numerical simulation

Figures

Figure 1 Time series of snapshots of the deposition of the Sn droplet in the case of the collision angle of 90 degree at the collision velocity of 4 m/s

Figure 2 Initial condition of single molten droplet dropping towards cooled substrate: left, horizontal substrate; right, inclined substrate.

Figure 3 Schematics of a solidification model

Figure 4 Behavior of the deposition phenomenon of single molten Sn droplet on the cooled plane horizontal substrate.

Figure 5 Behavior of the deposition phenomenon on the inclined substrate.