Newsletter 2022.11 Index

Theme : "20th The Dream of Flow Contest”

|

Demonstration of Portable electrical tomography system and its application

So Segawa

Chiba University

Abstract

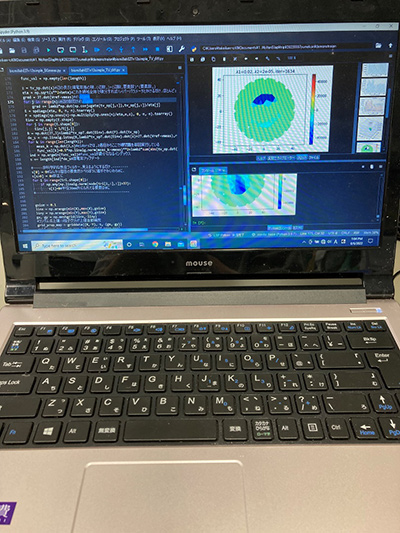

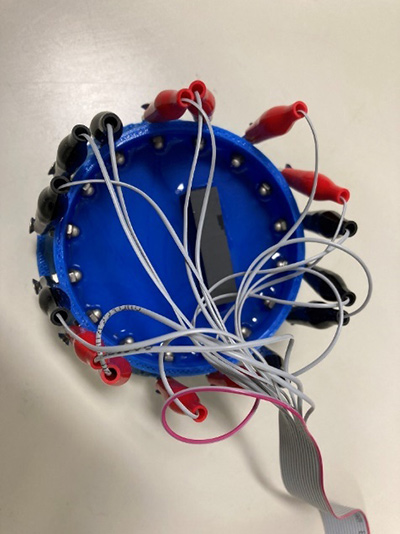

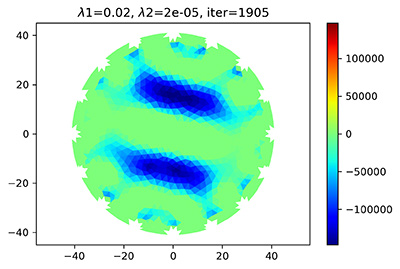

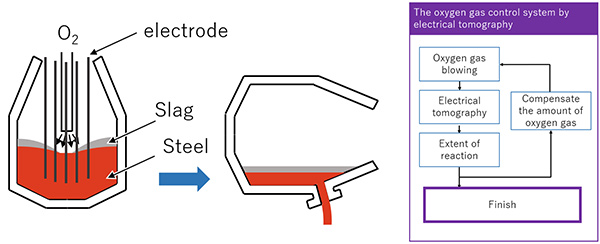

“Slag iron team” which includes Segawa and Yokomizo as members from the Department of Mechanical Engineering, Faculty of Engineering, Chiba University, received the “Ichijusho” prize at the 20th Flow Dream Contest on 7th August. The contest consisted of a presentation and demonstration and we made a “Portable electrical tomography system” to display. The system contained a laptop PC (Fig. 1), an electrical impedance measurement device, and a cup (Fig. 2). In the demonstration, the cup was attached to 16 electrodes, filled with tapped water, and set insulator on. The electrodes were connected to the impedance measurement device, which sent data to the laptop PC. The PC constructed the image of conductivity distribution on the cup by electrical impedance tomography computing (Fig. 3). In the presentation, we showed the idea of applying this system to steel manufacturing. In the current steel converter process, the amount of oxygen gas blown to adjust the purity of the steel relies on the experience of engineers. Then we proposed a system to control the amount of oxygen gas by electrical impedance tomography measurement. The system got conductivity distribution and extent of reaction in the converter, used for feedback to control the amount of oxygen gas (Fig. 4). This system will achieve a high-quality steel converter process. We appreciate everyone who made this opportunity and cooperated with this work.

Key words

Electrical impedance tomography, steel converter

Figures

Fig. 1 PC used for demonstration and an image of the conductivity distribution by electrical tomography

Fig. 2 A cup to put tapped water and an insulator object on

Fig.3 An image of conductivity distribution by electrical tomography using two rectangular electrical insulators

Fig.4 The electrical tomography system in steel converter