Planar elongational rheometer with two-dimensional opposing jets nozzle for mobile fluid

Manabu KATO National Institute of Technology, Tsuyama College  Tsutomu TAKAHASHI Nagaoka University of Technology |

Abstract

Planar elongational viscosity is one of the fundamental material properties. Especially, it is essential property to consider polymer processing such as blow processing, film processing, coating flow. For uniaxial elongational viscosity, there are several types of rheometer has been commercially released. Thus, we can choose elongational rheometer according to a purpose. Likewise, planar elongation, many researchers have been reported on the techniques to measure planar elongational viscosity for mobile fluids. However, the issue doesn’t achieve commercially available rheometer for measuring planar elongational property. Therefore, development of planar elongational rheometer remains one of the main issues of rheology.

We have developed the new elongational rheometer that can provide planar elongational viscosity for mobile fluids. This new rheometer use stagnation flow to generate planar elongational flow and equipped mechanical and optical measurement technique to measure elongational stress. The rheometer has a pair of nozzles that is sunken into reservoir filled with sample fluid. Two-dimensional opposing jets nozzle flow is made between the nozzles. We measure both flow birefringence along stagnation line and force acting on the nozzle. In the case of the sample fluid obeys stress optical rule, both optical and mechanical measurement can be available to measure elongational viscosity. Even if the sample fluid doesn’t obey stress optical rule, the rheometer can provide important data by using mechanical technique.

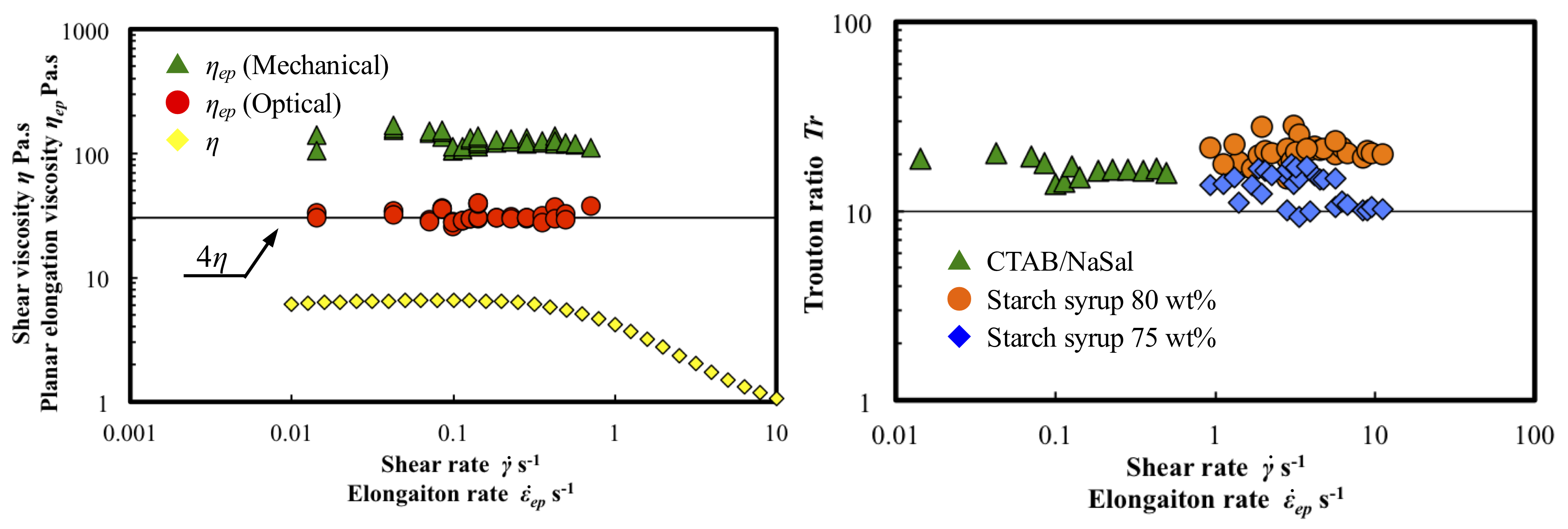

In this research, we demonstrate this new elongational rheometer with Newtonian fluid (Starch syrup aqueous solution 75wt%, 80wt%) and Maxwell fluid (CTAB/NaSal 0.03/0.23 mol/L aqueous solution). Figure.1 shows elongational viscosity for CTAB/NaSal aqueous solution. Optical data shows good agreement with 4 times of shear viscosity. Since Trouton ration of Maxwell fluid is Tr=4, this agreement shows optical technique of this rheometer has capability to provide precisely planar elongational viscosity. In contract, planar elongational viscosity from mechanical data shows about 5 times larger value then the data predicted from shear viscosity. However, mechanical data shows constant value with respect to elongational rate and it shows qualitatively agreement with optical technique. Finally, we compare Trouton ratio for CTAB/NaSal aqueous solution and starch syrup aqueous solution. Figure.2 shows that Trouton ration of mechanical technique becomes a constant value with respect to sample fluid and elongational rate. This result suggests that this new rheometer can provide valuable data not only qualitatively but also quantitatively by using correction factor.

Keywords

Planar elongational viscosity, elongational rheometry, Optical rheometry, Oppsing nozzle jets flow

Figures

Fig.1 Planar elongational viscosity measured by mechanical and optical techniques. Both results keep a constant value. Optical result coincides with 4 times of shear viscosity.

Fig.2 Trouton ratio of starch syrup aqueous solution and surfactant aqueous solution. They are evaluated from mechanical results. All of Tr show a constant value and they are approximately Tr=20.