Newsletter 2021.4 Index

Theme : "The Conference of Fluid Engineering Division (April issue)”

|

Is viscoelasticity of non-Newtonian fluids influenced by dispersion condition of particles?

|

Abstract

In control volume of multiphase fluids such as dilute solid particle suspension, its effective viscosity, μ*, is theoretically derived as η = μ*/μ = 1 + 5φ/2 by A. Einstein. At least to ensure the assurance of the estimation, the bulk volume fraction of dispersed particles is required to be dilute, homogeneous, perfect spherical shape, neutrally buoyant, and Newtonian viscosity. In the case of non-Newtonian fluid having viscoelasticity, the story is quite different: The dispersed particles spontaneously align in the sheared direction under unsteady shear flows. Utilizing ultrasonic spinning rheometry, we revealed the mechanism of the macro-rheology of non-Newtonian fluids causing particle alignments as follows: (ⅰ) The dispersed particles make alignments in the sheared direction under unsteady shear flows when the fluid relaxation time is sufficiently long. (ⅱ) The alignment changes the effective viscoelasticity because a corded-like pattern of particles functions as a macro-spring effect and reduction of particle interactions. (ⅲ) The distance of the aligned inter-particles is modulated according as the relaxation time of fluid media changes. (ⅳ) The clearer particle alignments are, the more the viscoelasticity is modulated as macro-rheological characteristic. Further we clarified factors aligning the dispersed particles by numerical simulations based on a simple toy model, which assumes dispersed inter-particle combined by effects of spring having yield stress. In conclusion through the findings of experiments and simulation in this study, the following cause-and-effect sequences are revealed; the relaxation time of fluid media causes alignment of the dispersed particles; the aligned particles cause modulation of effective viscoelasticity as macro-rheology.

Key words

Rheometry, Viscoelasticity, Unsteady flow, Particle alignment, Toy model simulation

Figures

Figure 1 A picture taken from the top of cylinder, showing aligned particles in PAM solution under oscillatory flow.

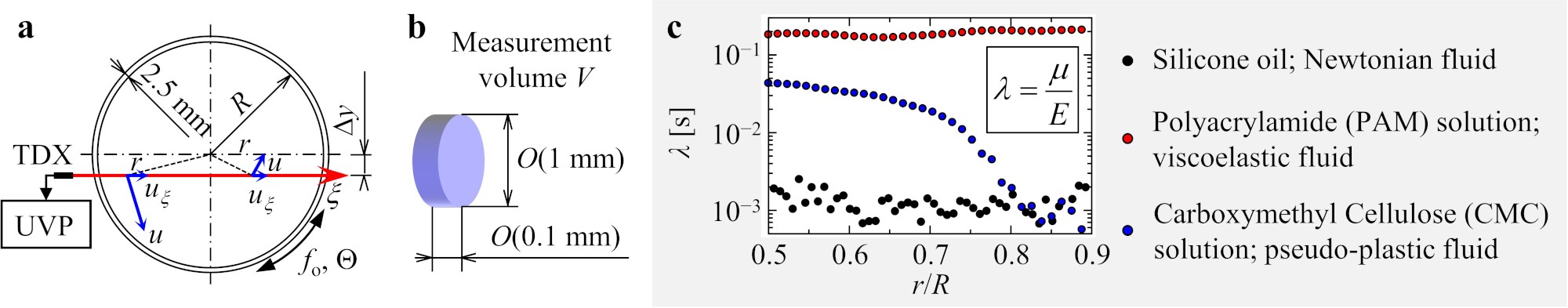

Figure 2 Schematics of (a) experimental setup and (b) measurement volume of ultrasonic pulse, and (c) radial profiles of relaxation time λ calculated from the evaluated results.

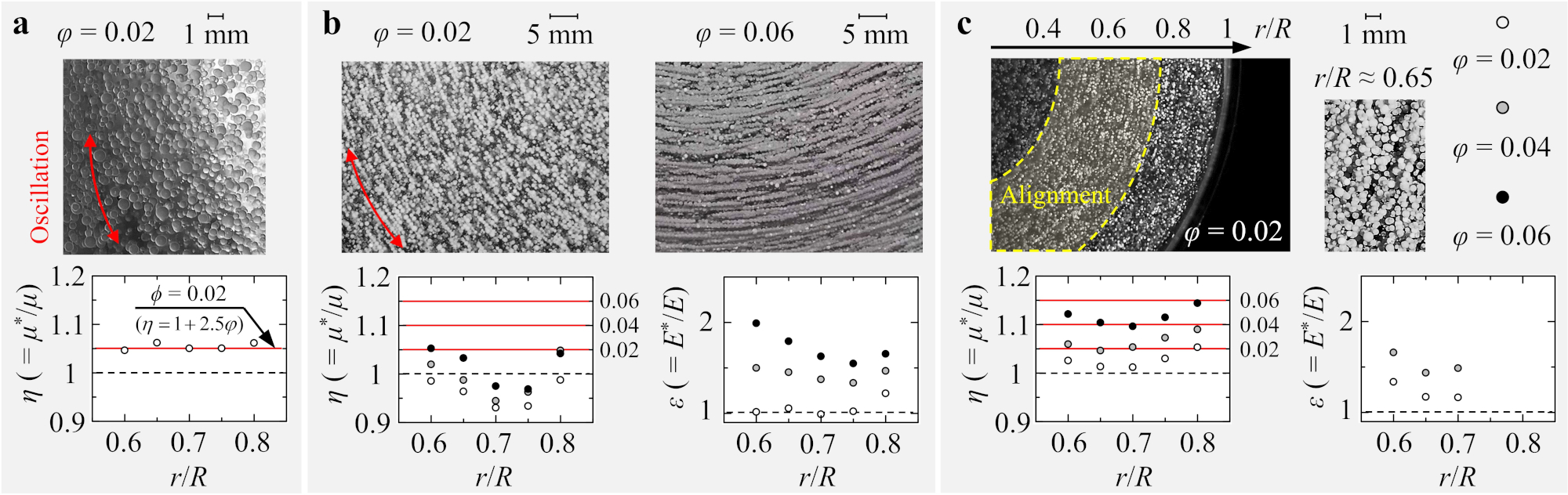

Figure 3 Photograph taken from the top of the cylinder during oscillations, and radial profile of the relative viscosity η and the relative elasticity ϵ, where the solid line indicates the relative viscosity estimated by Eq. (1); (a) silicon oil, (b) PAM solution, and (c) CMC solution.

Movie 1 Movie of toy model simulation