Newsletter 2025.3 Index

Theme : "The Conference of Fluid Engineering Division" (Part 2)"

|

Simultaneous multi-point measurement for thickness distribution of rivulet-like liquid film flow using fiber-optic probes

|

|

| Kosuke NAKANO Shizuoka University |

Yuki MIZUSHIMA Shizuoka University |

Abstract

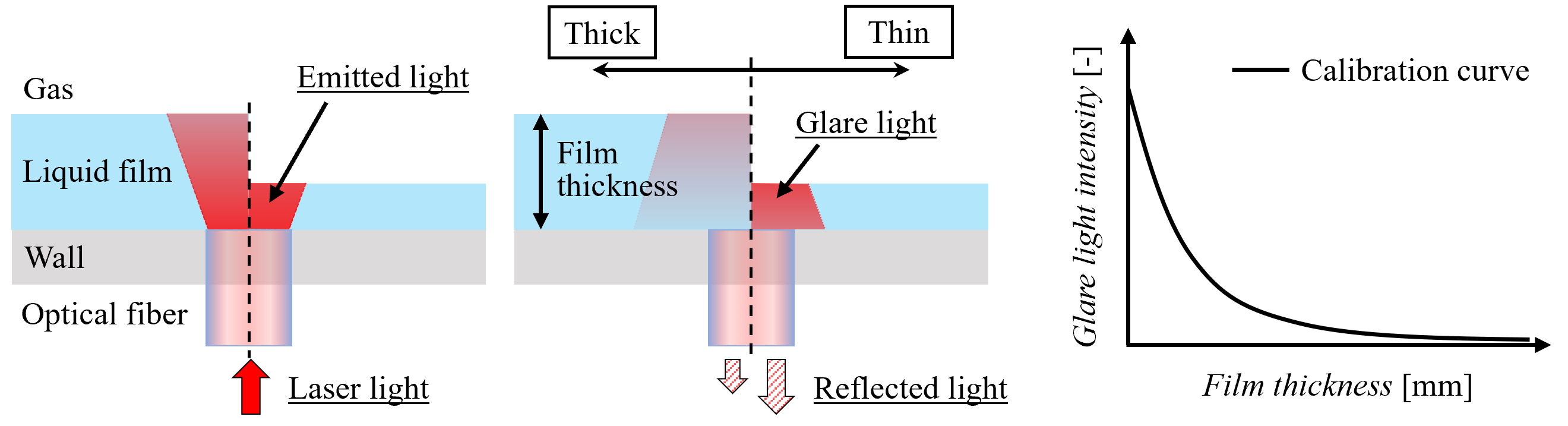

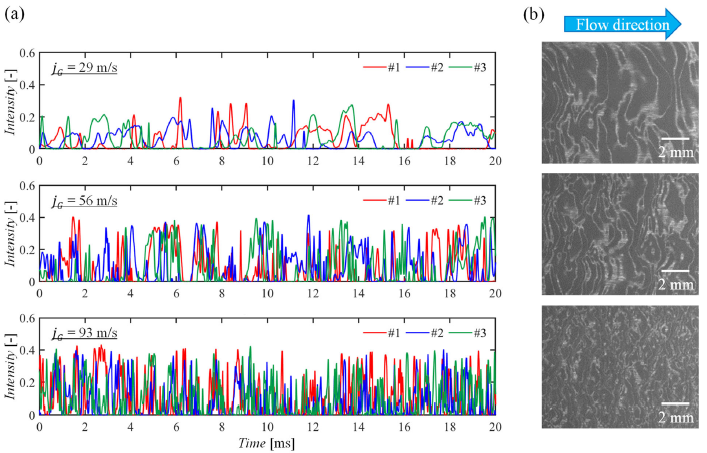

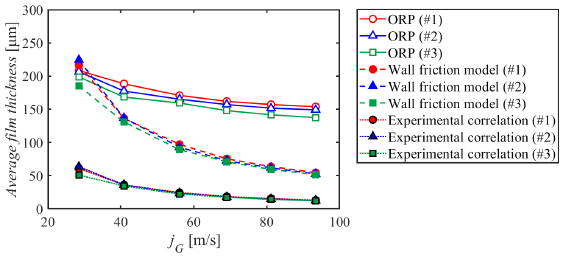

To ensure safe and efficient operation of industrial equipment, it is necessary to develop a liquid film sensor capable of accurately measuring the thickness of the rivulet-like liquid film flow that forms in extreme environments. Therefore, we have developed a method for measuring the film thickness using an Optical-fiber-based Reflective Probe (ORP). This method is based on a simple but robust measurement principle that uses the light intensity reflected by the liquid film surface, as shown in Fig. 1. The effectiveness of thickness measurements via a single ORP in shear-driven liquid film flow was verified experimentally and numerically. This study newly measured the thickness distribution in the flow direction of a rivulet-like film flow by using a multi-point ORP measurement system and the experimental apparatus shown in Fig. 2. As shown in Fig. 3, a comparison of the response signal derived from the ORP with the interfacial wave shape obtained by a high-speed camera confirms that the ORP has enough temporal response to follow instantaneous thickness fluctuations in the thin-film interface. Further, by analyzing the film thickness measured by the ORP for each gas velocity and measurement position, we examined the applicability of the conventional model equation for liquid film thickness, which was constructed based on the measurement results at a single measurement point (Fig. 4). The difference between the experimental and estimated values indicates that the formulation of a universal model for estimating the film thickness needs to develop a correlation for the friction factor at the liquid film interface based on two-phase flow experiments, considering the film thickness distribution in the width direction.

Key words

Liquid film flow, Rivulet, Thickness measurement, Optical-fiber-based Reflective Probe

Figures

Figure 1 Measurement principle of the Optical-fiber-based Reflective Probe.

Figure 2 Schematic of the experimental apparatus.

Figure 3 ORP signal characteristics, (a) Typical output signals of the ORP, (b) Enlarged images of the rivulet-like liquid film flow.

Figure 4 Comparison of average film thickness evaluated by the ORP and the model equation.