Newsletter 2025.3 Index

Theme : "The Conference of Fluid Engineering Division" (Part 2)"

|

Fabrication of Cellulose/Silver Composite Filament by Nozzle Flow with Applied Electric Field

|

|

|

| Wakana HIRA Tohoku University |

Yutaka KANEKO Tohoku University |

Hidemasa TAKANA Tohoku University |

Abstract

Cellulose nanofibrils (CNFs) are the fundamental building blocks extracted from wood and are fibrous materials with a high aspect ratio. The fabrication of CNF single filaments with superior mechanical properties from CNFs dispersion can be achieved by aligning CNFs along the filament axis. One method for fabricating strong CNF filaments utilizes a nozzle flow with applying electric field, enabling the hydrodynamic and electrical alignment. In this study, the fabrication of cellulose/silver composite filament with superior mechanical properties and antibacterial property is demonstrated by using a nozzle flow with applied electric field. In addition, the effect of the amount of loaded silver nanoparticles on the mechanical properties of composite filaments is clarified.

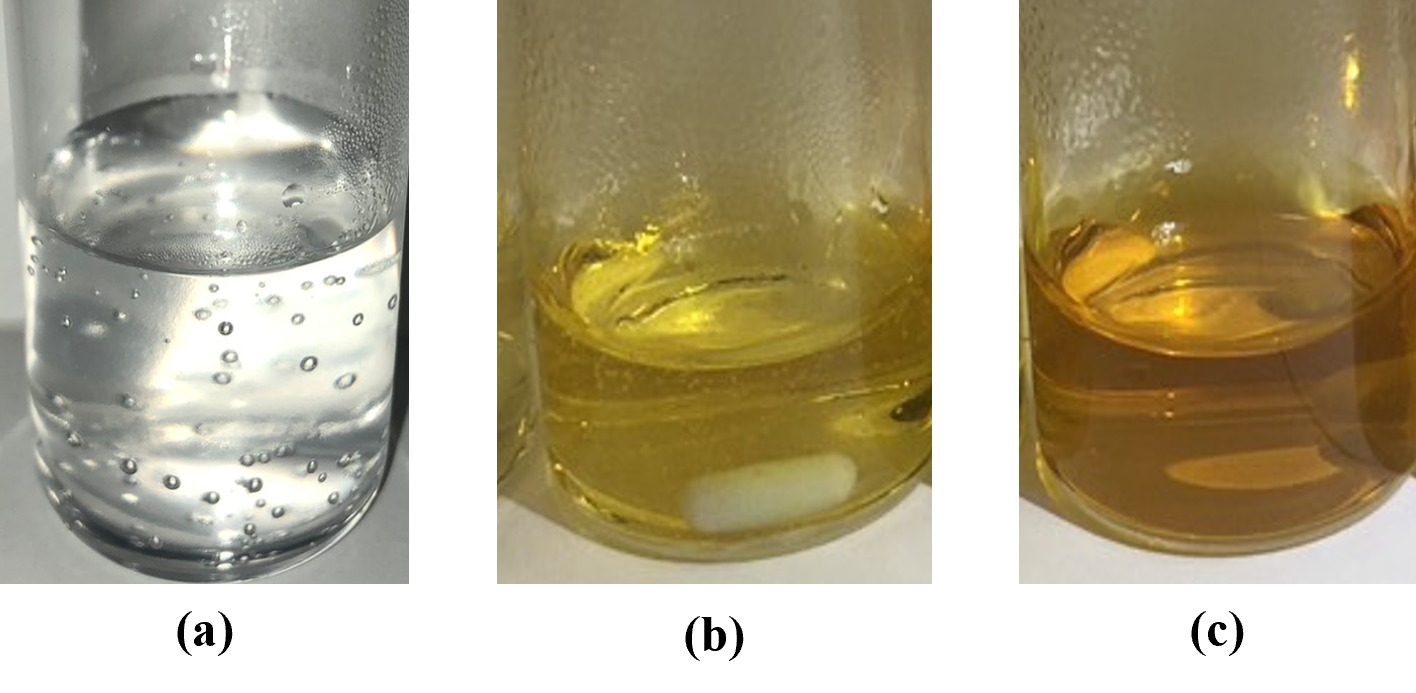

CNFs dispersions loaded with silver nanoparticles were prepared by mixing of CNFs dispersions and Tollen’s reagent at 80 ℃ for 2 hours. Figure 1 shows photographs of the CNFs dispersions and those loaded with silver nanoparticles. The addition of Tollen’s regent causes a color change in the dispersions, changing from yellow to reddish-brown as the ratio of Tollen’s regent increases. Because the color change is due to the surface plasmon resonance (SPR) of the silver nanoparticles, it confirms successful loading of silver nanoparticles onto CNFs.

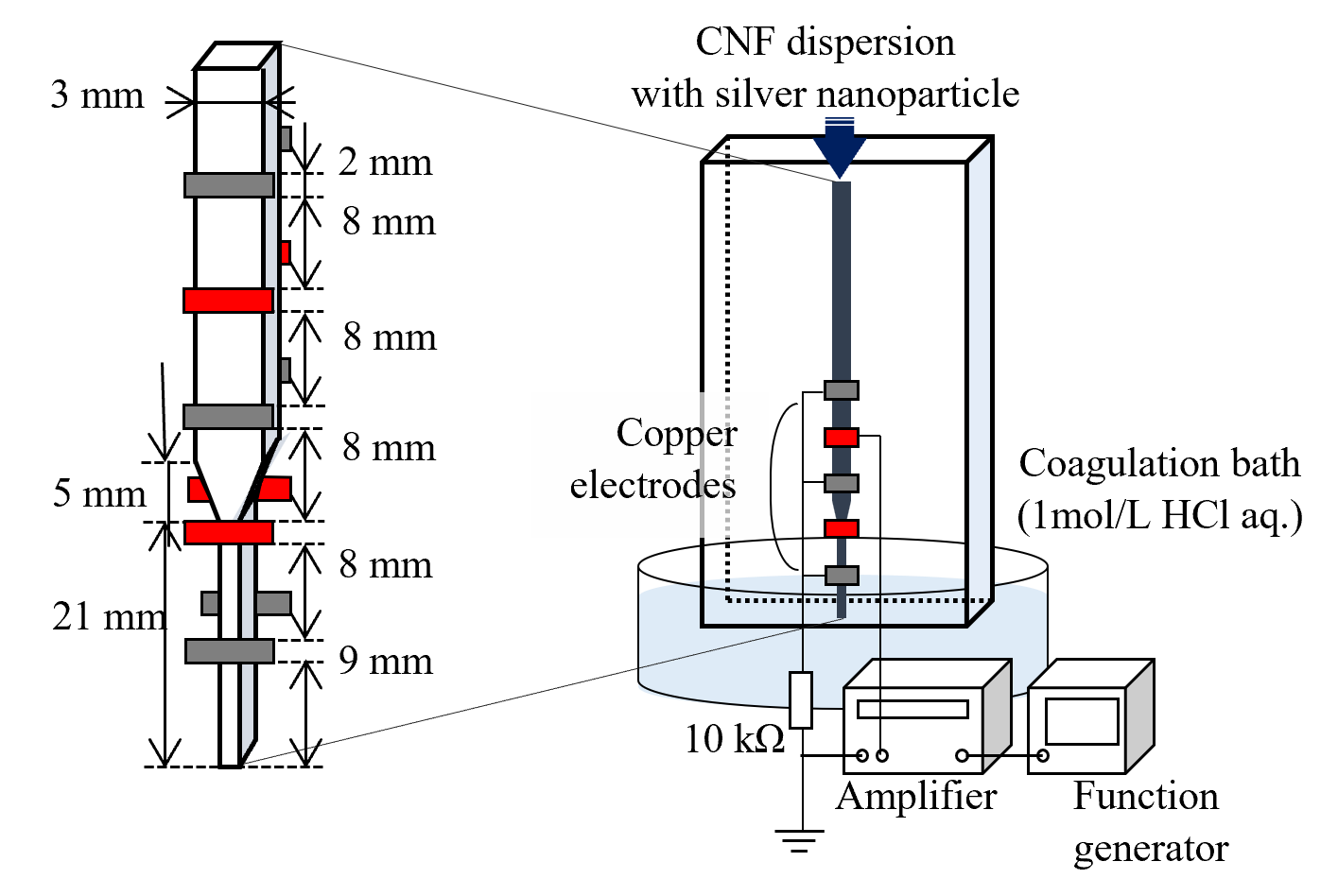

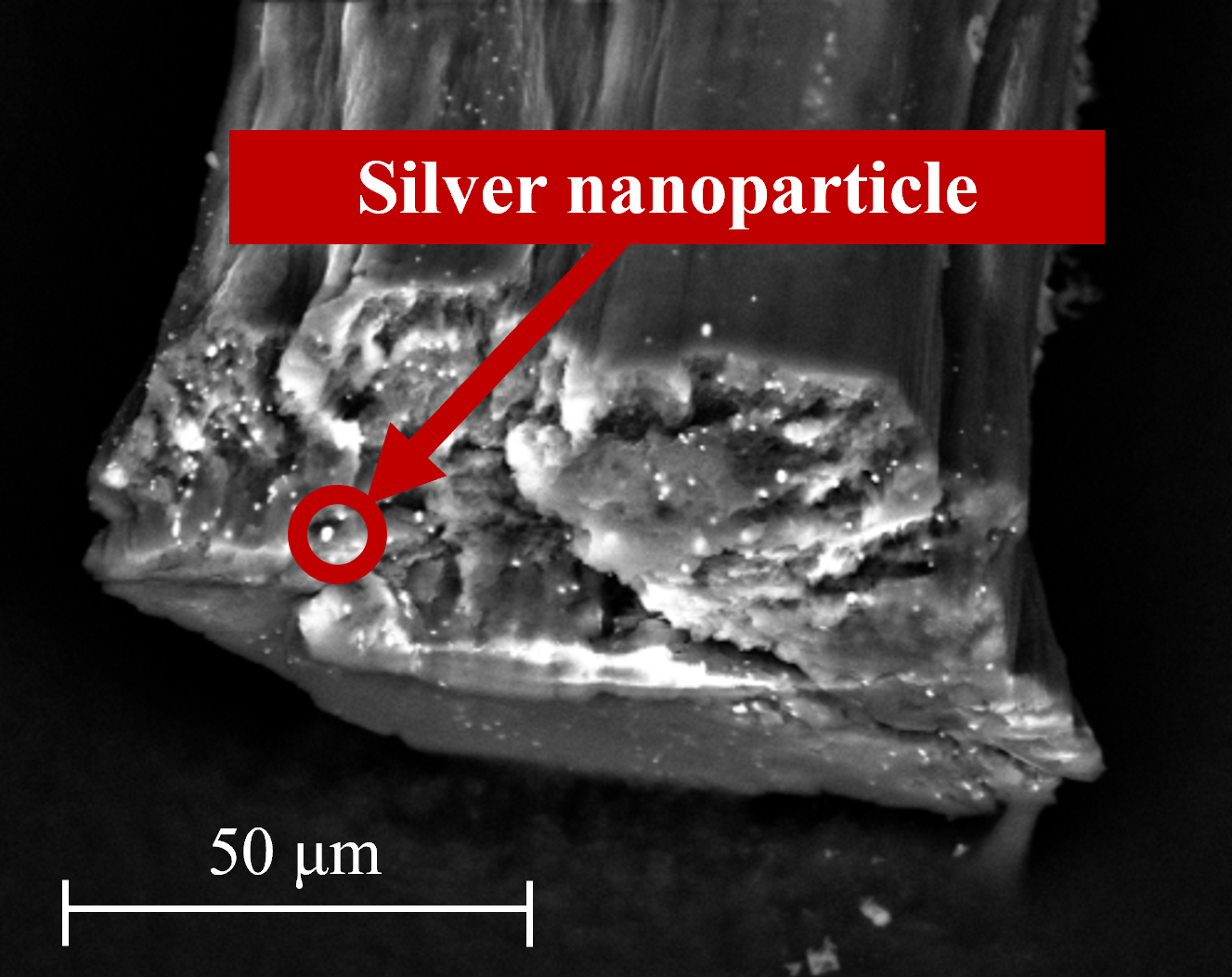

Cellulose/silver composite filaments are fabricated using an electric field applied nozzle flow shown in Fig. 2. The SEM image of the cross-section of the composite filaments (Fig. 3) reveals that silver nanoparticles are uniformly dispersed inside the filaments. Through antibacterial tests of the filaments using natto bacteria, the distinct antibacterial properties of the composite filaments were confirmed.

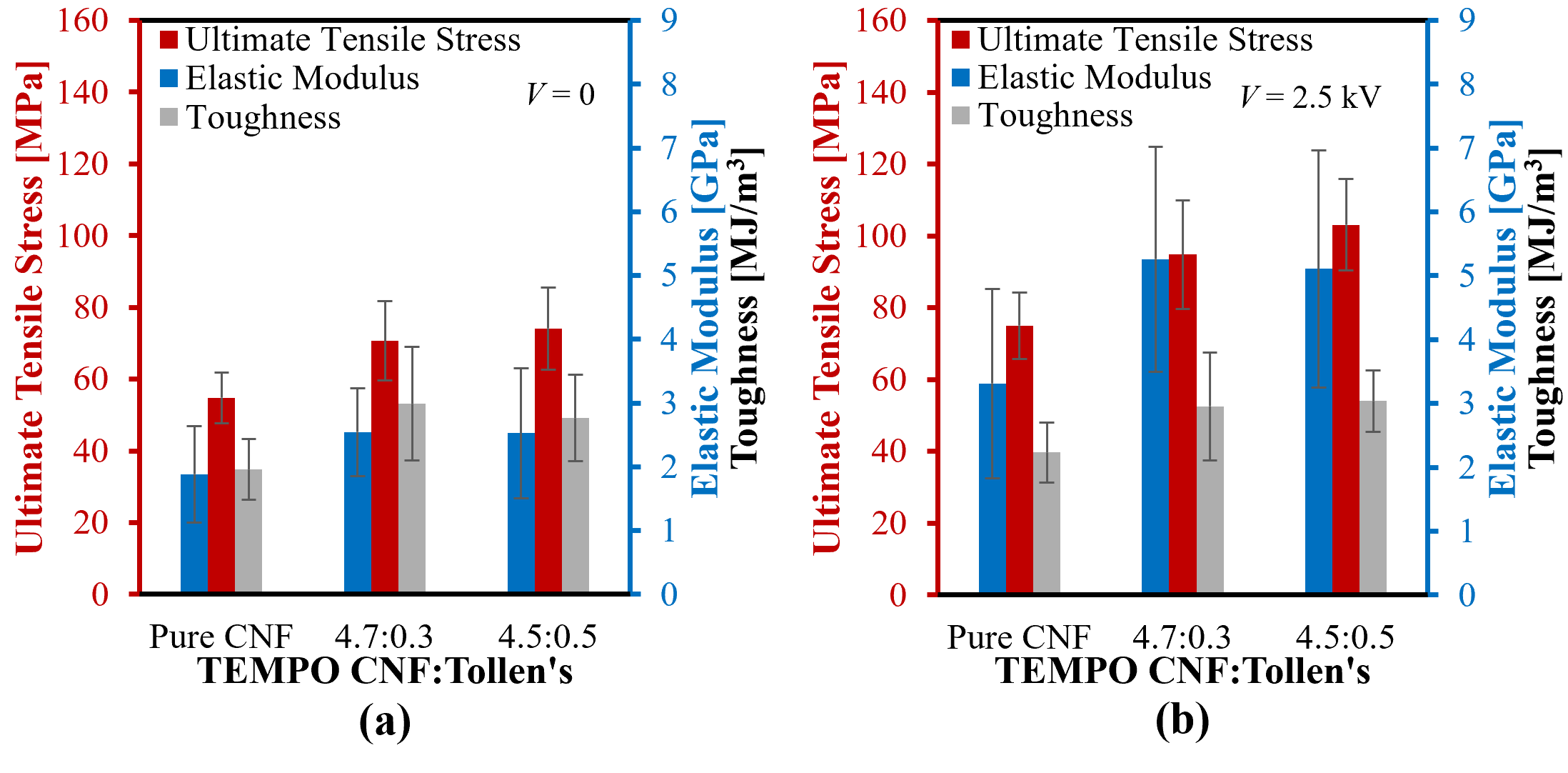

Figure 4 (a) shows the mechanical properties of the composite filaments fabricated without an electric field. Increasing the silver nanoparticle loading ratio improves the tensile strength. The decrease in dispersion viscosity under high mixing ratio enables the rotation alignment of the CNFs more easily, which enhances the alignment along the fiber axis, resulting in the improvement of the mechanical properties. Figure 4 (b) shows the mechanical properties of the composite filaments fabricated with applied electric field. In all conditions, applying the electric field further enhances the tensile strength and elastic modulus of the filaments. For the mixing ratio of CNF:Tollen’s = 4.5:0.5, applying an electric field increases the tensile strength, elastic modulus, and toughness by 39%, 102%, and 10%, respectively. This indicates that CNF alignment by the electric field is effective even for CNFs loaded with silver nanoparticles, leading to a significant improvement in mechanical properties of the composite filaments.

Key words

Cellulose nanofibril, Cellulose filament, Silver nanoparticle, Electric field assisted alignment, Antibacterial filament

Figures

|

Figure 1 Images of Ag-CNF dispersions for different mixing ratio of CNF and Tollen’s regent, |

|

| Figure 2 Schematic illustration of experimental setup. |

|

Figure 3 SEM images of cross-section of cellulose/silver composite filament fabricated under CNF:Tollen’s = 4.5:0.5. |

|

Figure 4 Mechanical properties of cellulose/silver composite filaments fabricated (a) without electric field and (b) with electric field (2.5 kV). |